Closures and Liners Shortage: What’s Happening and What to Expect

What Is Going On?

In short, the supply of closures and liners has been severely challenged. While we have seen some improvements on closures (on the molding side), liner supply continues to be a challenge. TricorBraun is here to help.

It all started with ice storms. The severe weather that hit Texas in February exacerbated the preexisting COVID-related shortages in the polypropylene (PP) used to make caps and other closures—and things just deteriorated from there. Here’s what happened, and how TricorBraun continues to respond to protect critical industries and keep our customers supplied.

Why Is It Happening?

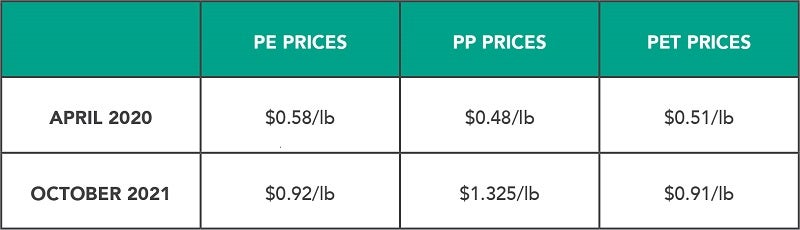

Even before the winter ice storms even hit, there was a resin shortage due to soaring demand for closures, PET bottles, and HDPE bottles for cleaners and hand sanitizing products. (And once people started buying fewer hygiene products, the demand shifted to vitamins and other nutraceuticals.) Then the deep freeze caught everyone by surprise, leading to electric grid failures, cracked factory pipes, and roads so iced over that trucks were unable to get in and out. As PE factories temporarily shuttered, the price of polyethylene rose sharply.

Meanwhile, closure liners were also in high demand. Liner companies, like molders, compete for resin supplies, foil, and other raw materials. The huge increase in e-commerce during COVID drove demand for lined closures. Currently, that demand is outpacing supply.

Although liner companies use only a little bit of PE in their formulations, they nonetheless need that same resin to manufacture their products. In addition to much higher prices for raw materials, the liner companies were hampered by COVID-related labor shortages. Foil is now also in short supply due to freight challenges in the US and abroad—and demand is outpacing supply. All of this has created spot supply shortages and very long lead times.

The Result

At the height of the uncertainty, lead times for closures and liners were 40–60 weeks out. This has since come down for smaller diameter closures. Liners, however, are still a contributing factor to long lead times.

No one had enough supply. Priorities were given to those customers producing heart, lung, and other medications where alternative resins or colorants couldn’t be used and where any delay could mean the difference between life and death. To address the severe shortage, TricorBraun’s supply chain management team was searching around the country and across the globe to identify closures and liners to meet customer demand.

What to Expect

The good news is that the situation is a little better now.

Some cap supplies are improving, though others remain tight. While the major liner companies are investigating additional production capacity and labor to support growing demand, supplies will likely remain constrained until at least Spring 2022.

Strong Supplier Networks, Warehousing Capacity Offer Buffers

3 Tips for Closure and Liner Supply Continuity

Are you looking for more certainty in your supply chain? Here are three ways that you and your sales rep can work together:

- First, consider a warehousing agreement. A warehousing agreement will allow TricorBraun to hold closures and liners in supply for you. This will buffer you against some supply disruptions.

- Second, qualify alternatives. The more options you (and we) have available upfront, the easier it will be to flip the switch and keep you in supplies.

- Third, share your forecasting. In addition to your annual forecast, it’s important to share with your sales rep any promotions you might have that could spike sales. The more lead time we have to find your closure and liner supplies, the better.

The supply chain will improve—including for closures and liners. But it’s going to take time and patience. Meanwhile, TricorBraun is here to help you navigate through this challenging time.

TALK TO A PACKAGING CONSULTANT

Whether you’re looking for a stock package or a groundbreaking custom design, TricorBraun’s proven process will guide your packaging decisions from napkin sketch all the way to the retail shelf.